How good is wood? Better than some in the steel biz say it is.

No building material is perfect, but I wish people weren't so critical of their competition. Every material has a role to play.

Julian Bowron is a friend; he is the first person I had a beer with after the pandemic. He’s the principal of Metaloq International and makes an exciting steel prefab framing system. He recently commented on a LinkedIn post critical of Mass Timber in construction and jumped in with some “questions”:

I like Julian, so I thought I would try to be helpful and answer his questions as best I could. Since I can’t do it over a beer at The Hole in the Wall, I thought I would do it here.

1) How is a 6" thick solid wood wall or floor more sustainable than a wall or floor with a 2" x 6" or 2" x 12" member every 16"?

It’s not. That 6” CLT wall uses five times as much fibre as the framed wall and probably costs many times as much money, which is why, except in special circumstances, nobody does it. Generally, in North America, if the code permits it, everyone uses wood framing. Besides, we are comparing wood to steel, not wood to wood; the question isn’t relevant.

2) How long does it take for a forest that is cut down to reach the same rate of carbon uptake? And what about the biodiversity and resilience of plantation forests?

It doesn’t ever reach the same level. As Will Hawkins notes in his discussion of timber and carbon sequestration, “It is still better (for the climate) to build nothing at all than a timber building.” But building nothing isn’t on the table, so the question then is which material does the least amount of harm. Hawkins notes that “Timber must be sustainably sourced, with replanting, for any potential embodied carbon benefits over concrete and steel to be realised.” But when it is done properly, the benefits are significant.

3) What happens to CLT / LVL etc. at the end of its service life? It is always mixed with adhesives, and often has metal, coatings and / or concrete mixed with it. Will it always be shredded, sorted and burnt? Or buried in a landfill to then turn in to methane?

There are a number of answers here. If the building is designed by Waugh Thistleton, the wood is “screwed, not glued” so it can be dismantled and the wood reused. Many buildings are built with DowelLam, or Dowel Laminated Timber, so there are no adhesives holding it together.

I am writing this post on a massive slab of nail-laminated timber that was a 1950s era bowling alley in a building I converted to housing when I was an architect back in the 1980s; my dad welded the frame at his factory, and it is now close to 40 years into its second life. Try doing that with a concrete or composite floor.

Julian then decides to answer his own question:

Turns out that the forests that are cut take a big hit to their ability to absorb carbon. So for at least 50 years, cutting the forest actually accelerates climate change. The emergency is now, not coming in 2075.

Julian is referencing research discussed by Max Vittrup Jensen claiming that carbon stocks in the humus soil layer might take 50 years to recover. Nobody is actually sure about how much carbon is lost from the soil or how long it takes to recover; I asked Peter Moonen of the Canadian Wood Council and he told me that every forest and every soil condition was different. But the point is it does recover. Furthermore, the hit isn’t instantaneous as it is with making steel.

Julian says The emergency is now, not coming in 2075. Exactly my point! Making steel is responsible for between 7% and 11% of global carbon dioxide emissions right NOW. Julian is forgetting the time value of carbon emissions- now emissions matter more than later emissions. You don’t burn fossil fuels to produce mass timber, except for powering the trucks. I also don’t particularly care about 2075, I care about NOW, about every kilogram of CO2 going against the budget NOW.

Julian then notes that the steel industry is getting better. It’s true!

Steelmakers in the EU and Algoma Steel Inc. in Canada are well along the path to reducing the carbon footprint of steel used in construction by 70% or more. Steel is already the most recycled material on earth with much of the recycling being done with electric melting.

However, 72% of the world’s steel is still made in blast furnaces, with a forecast that it will be down to 60% in 2035. There will never, ever be enough recycled steel as long as primary demand is not reduced. And an excellent way to reduce primary demand is to substitute wood wherever possible.

I am not totally in the tank for mass timber; I believe it has to be used responsibly and carefully. That’s why I start this post with an image of Waugh Thistleton’s Black and White building; Andrew Waugh says it uses 40% less fibre per square meter than their earliest CLT buildings. I have often asked How good is wood and end up preaching the mantra- Use Less Stuff, including wood.

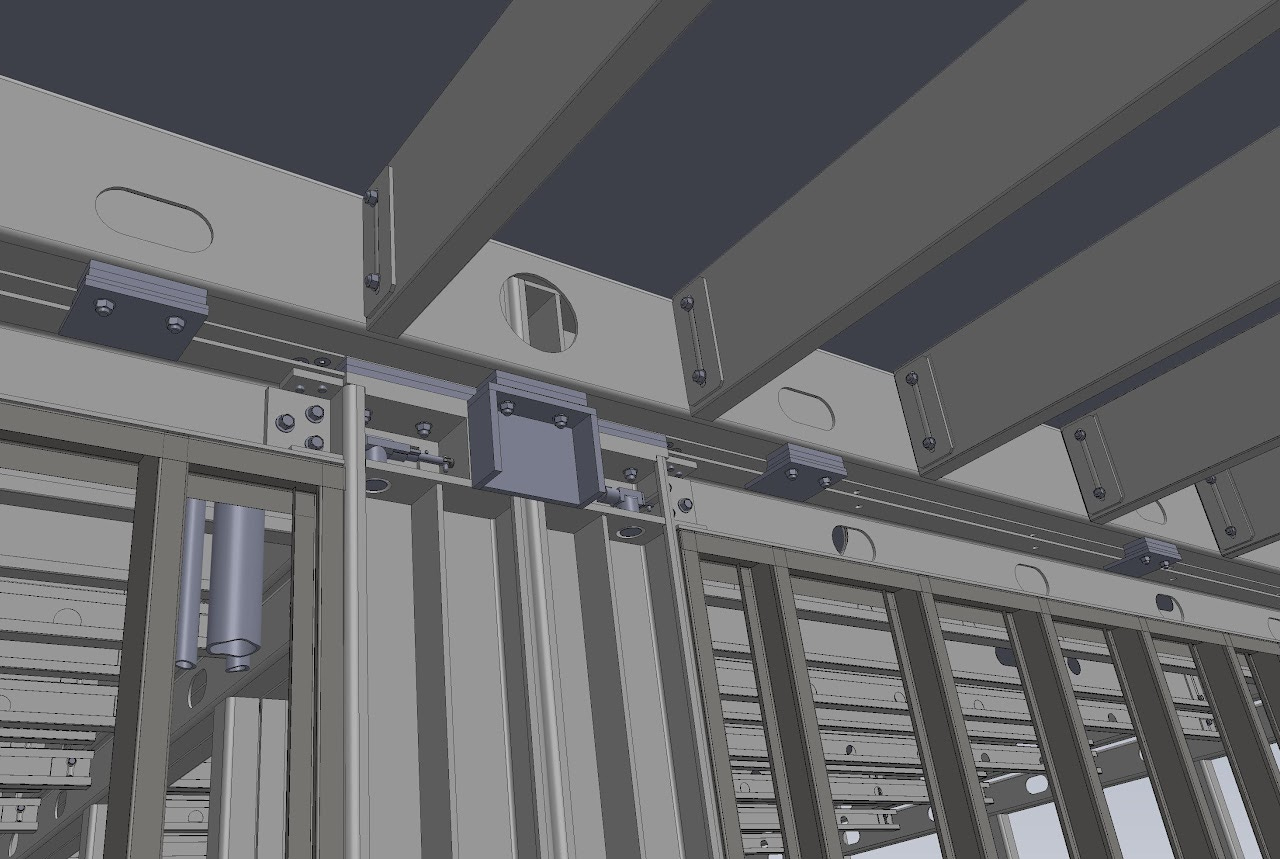

Julian Bowron understands the concept of using less stuff; he has designed Metaloq, a marvellous steel system that can do many things which wood can’t. It’s light and fast, and almost assembles itself.

But I just wish guys in the steel biz would toot their own horns instead of dissing wood. They both have roles to play.

Special offer!

I do not want to put up a paywall on this site, but it provides a meaningful portion of my income. So here’s a limited-time offer: I will send a signed copy of the print edition of “Living the 1.5 Lifestyle” to anyone in the USA or Canada who signs up for a one-year subscription (C$50, cheap at about US$35 ).

This seems to be a never ending discussion. Two quick things to add:

1.) the photo you show of the GLB connection "screwed - not glued". This connection would never be glued (or extremely rarely, until you research Stefan Zoellig in Germany). The glue refers to how the GLG (glue lam beam) is made, and unfortunately the G stands for glue. It wouldn't surprise me if it was about the same amount as the coating on the steal.

2.) we need to look at buildings holistically. Just comparing steel to wood does not always give the whole picture. A steel frame is almost always covered up, whereas mass timber buildings can often be left exposed (yes, we have entire buildings that were encapsulated timber, but that's also changing). One example: Toronto Montessori School. This building was originally designed to be built in steel. It is beautifully curved mass timber GLB now. When I asked the architect to elaborate on cost comparison, he brought to my attention that steel in and of itself would have been a lot cheaper, but would have been completely covered up too. Since the timber didn't have to be covered up, it brought the cost of the timber structure down by a lot. This also means that upfront carbon for this building was drastically reduced by not having to over up the timber.

Just my 5 cents.

Ps: I do agree that we need to work together and not vilify the other materials. Each have their strengths and weaknesses and we need to be strategic about them.