GeoHome may have solved the problem of the geodesic dome.

Finally, a dome that won't leak. I have the perfect spot to put one of these...

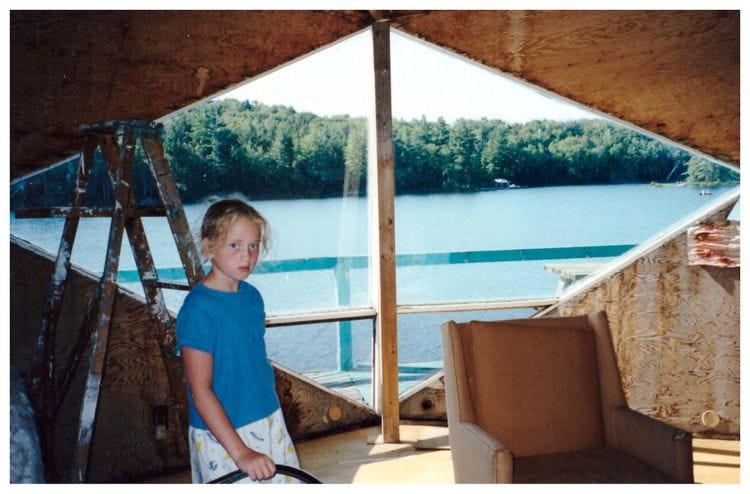

Back in the eighties, I was an architect renovating a cottage on Lake of Bays in Muskoka, Ontario, and I went into the local real estate office in Dorset to make some photocopies. It was a hot market at the time, but one listing on the wall wasn’t moving; It was water access (people want roads!), on a small lake (people want big boats!), and worst of all, it was a geodesic dome. (Domes are for hippies!)

It was cheap, I fell in love with it, and I bought it. On our first family visit, I tried to open the door while carrying my eight-month-old daughter; It was completely waterlogged, pulled off its hinges, and almost crushed us both.

This is a common story with domes; as I noted in my post Thinking About Building a Geodesic Dome? Don't, Their biggest problem is waterproofing; my dome had panels made of plywood with fiberglass insulation, and relied on a coat of fancy paint to keep the rain out. It didn’t work. Even experts like Lloyd Kahn, who wrote books about domes in the seventies, gave up and complained about the “short lives of modern materials, and as-yet-unsolved detail and weatherproofing problems.”

But these detail and weatherproofing problems may have been solved by Arctic Acres with their new GeoHome, launched at the National Home Show in Toronto. It is a marvel of clever engineering that anyone with experience with domes will appreciate.

There is a reason traditional walls have a gap behind the exterior cladding: drainage. Domes did not have a drainage plane and relied entirely on the skin. There is a reason houses have roof overhangs; to keep water off the walls. But in a dome, there are no roofs or walls, it is a continuous surface.

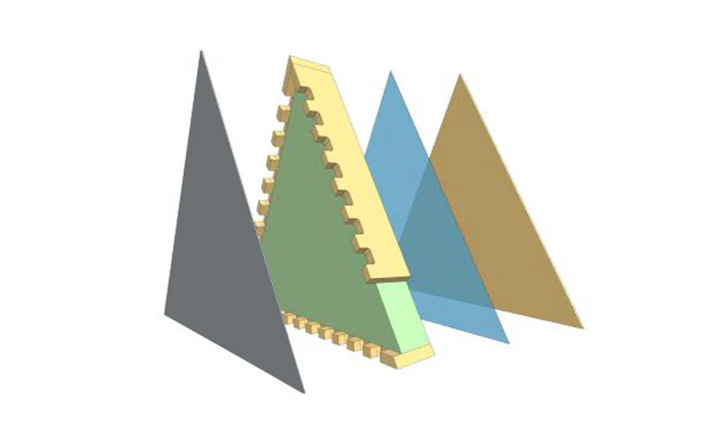

The GeoHome solves this with a very clever wall panel, with the structural members cut out on a CNC machine. After the triangle of insulation is installed, a waterproof membrane covers it edge to edge, leaving a gap between the insulation and the aluminum outer skin. The gap is vented top and bottom, which will help keep it cooler inside, reducing the expansion and contraction which eventually causes leaks.

I can’t overstate the importance of this; as GeoHome notes,

“By minimizing moisture accumulation and temperature extremes, the aerated shell helps protect the structural integrity of the geodesic dome over time. This not only enhances the longevity of the materials but also reduces maintenance costs, as fewer repairs or replacements due to water damage are required.”

The CNC machine enables remarkable precision; watch the 49-second video to see how this goes together. The floor assembly is amazing.

Here are the parts of a panel, starting with the CNC frame. They know their building science; from the GeoHome website:

“The T-SIPs are composed of seven layers that are designed to function together to provide both structural integrity and thermal insulation. Each layer serves a specific purpose in the overall performance of the panel:

Plywood interior wall, 4 mm thick

Vapor barrier film, 0.16 mm thick

Aluminum foil, .1 mm thick

PIR insulation, 100 mm thick

Aluminum foil, .1 mm thick

Ventilation gap, 29 mm

Aluminum composite panel, 4 mm thick

“The components of the T-SIPs include the individual materials and the design features that allow them to interlock to each and the floor to form a complete building envelope. Each panel is fabricated to precision to enable a tight, interlocking fit, which contributes to the structural integrity of the geodesic dome. The panel edges include built-in connectors that ensure the panels align and fit securely together during assembly. This interlocking system ensures accurate assembly, minimizes air infiltration, and provides a strong, unified structure.”

The interior is lined in plywood, finished beautifully. There is an optional interior divider to separate the space, but as both Lloyd Kahn and Lloyd Alter have noted, domes can be difficult to furnish. There are no opening windows in this demonstration model, but CEO Ben Canning tells me there are lots of options. For those who are not fans of polyurethane foam insulation, he’s willing to entertain options there too.

The GeoHome is built in Portland, Ontario, but would fit anywhere between Portland, Maine and Portland, Oregon. It costs C$60K, (US$41,756 and dropping fast with our loonie or going up with tariffs, I don’t know which) which is pretty cheap for 301 square feet of finished space. More at the GeoHome site.

Our dome was designed in 1969 by engineer Clare Lake, who had been inspired by the American Pavilion at Expo 67 and fabricated the sandwich panels in his garage. We used it for fifteen years until 2001, complete with water stains and 2x4 holding it up, which was a pretty good run for a plywood dome. I wrote in its obituary, “with every generation there is revived interest in geodesic domes and I only have one bit of advice: Don’t do it.”

But after seeing what Ben Canning and Arctic Acres have done with the GeoHome, I think I should retract that advice. They have figured it out.

Across the aisle from the GeoHome booth, the Green Building Learning Zone has a quote of mine on their booth, where I am still stressing the importance of air tightness, quality and “our houses have become lifeboats, and leaks may well be fatal.” I would never have put a geodesic dome in that category, but the GeoHome qualifies.

Note 1: On Pi day one year I wrote a relevant post, "Mr. Fuller, Why Would You Build a Round House?"

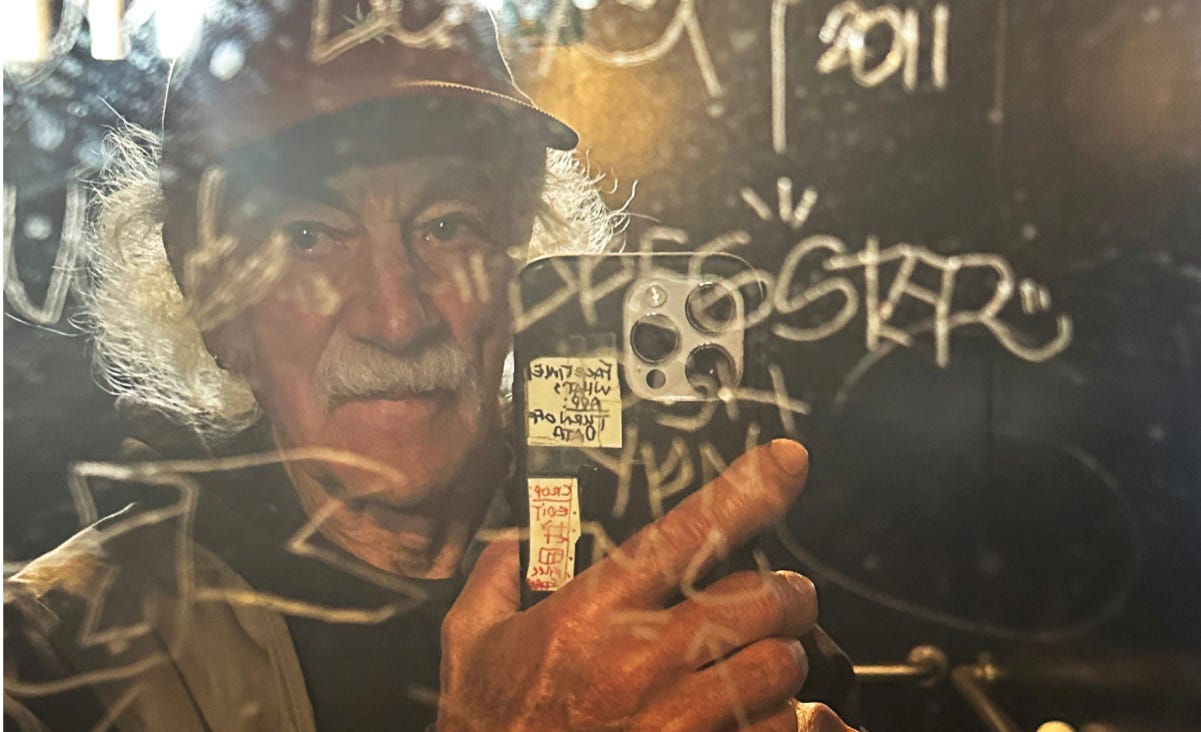

Note 2: Lloyd Kahn, author of Domebook 1 in 1971, has been an inspiration for many years, but lately less about building things and more about how to grow old. He just resurfaced a post he wrote last year about turning 89.

“Nature is trying to compost us. To pull us back into the basic elements from which we came. Older people get stooped over; it’s gravity pulling us back into the earth. The wear and tear of the years, plus nature’s timetable, are steadily subtracting physical skills and abilities, so as you age, it’s a dance — of coping, of adjusting, of doing whatever you can to continue life as robustly and as vital as possible.”

So at 89 he surfs, paddles, cycles, hikes, and skateboards. It’s a wonderful read at The Final Lap, or What It's Like to Be 89. Here is his update where he also says nice things about domes, eating some of his former words.

I recently finished reading the latest biography of Buckminster Fuller. Was fascinating and frustrating how determined he was to invent a standardized container dwelling despite the intractable challenges of fitting mechanical systems and furniture. It didn't start with geodesic domes at first, but his commitment to promoting domes only led to any success as a public novelty and most functionally as a Radome (which are kinda neat).

I think of myself as a bit of a hippy but I never got the fascination with dome houses. They always struck me as a neat looking but impractical solution for anything other than temporary tent like structures. They look good on paper. Cheap to heat, open floor plan allows flexible interior design, structurally robust, amenable to factory/prefab construction, offer good options for bringing in natural light, etc. In real life they seem to be a novelty destined to be a pita. Taming the weather/moisture problem is no mean feat. The number of exposed non vertical seams pretty much guarantees leaks in any environment that has any significant heat and or moisture fluctuations over time. The quality of material and level of precision in manufacturing and assembly required to address this problem are difficult to obtain in practice. Building spaceships in a lab is much different than living in them in a four season environment. Construction that actually is able to address the leak problem is likely to be expensive and not amenable to do it yourself construction, maintenance or repair. Operating costs will get costly over time (or you get disposable buildings). Building SIP’s that can fully exploit the geodesic dome shape to maximize its natural advantages regarding heating imposes another difficult construction exercise that is unlikely to produce results that will stand the test of time. In general, the level of technology required to build them well enough to overcome their inherent challenges means there is little room for DYI’ers here (count me out in this point alone). $60k without a foundation for 300sqft does not sound cheap to me and I would guess that you are looking at 50% or more on top to have it built on site. I, with a couple of semi skilled, handy helpers and material on site could probably build a similar size rectangular, wood frame, fully insulated (r30 in the walls and floor and R40 in ceiling), well lit, steel roofed building (including floor and pad footing) for half that amount in little more than a long weekend. It will last 50 plus years with minimal maintenance and without requiring any significant repair and even then a new roof and and some some minor repair will set it up for another 50 years of service. Maybe geodesic domes will find a place on the moon or Mars someday but I think they will remain a novelty here.

P.S: I am still not a fan of airtight buildings despite the math on the energy use advantages. Again, the level of technology required to do it well is significant, expensive and prone to failures that create serious health risks, it requires significant and expensive maintenance, (no DIYers please ) and it encourages building bigger than necessary by promising low heating and cooling costs. There are lots of simple, low tech, effective, practical ways to make healthy, durable, smartly efficient buildings that can stand the test of time. Build low, build small, build strong, build simple and don’t throw out the baby with the bath water when trying to find a better way to get something done.