“Fist pumps for R290 Monoblocs!”

Journalist David Roberts once wrote "Fist pumps for heat pumps!" but we have to be more specific.

Over on Linkedin, there was a brief discussion about how refrigerants in heat pumps are significant greenhouse gases, a subject I discuss in my upcoming book from New Society Publishers, The Story of Upfront Carbon. I complain that in the headlong rush to electrify everything, with the cri de cour being “Fist pumps for heat pumps!” people, including architects, don’t understand the implications of the refrigerant choices. A commenter noted, “That’s why we have consultants,” but I am not sure they get it either. Here is an excerpt, edited and updated, from my book where I try and explain the importance of the issue.

Heat pumps have been in our homes for a century; your refrigerator is one. It has an evaporator side where a chemical chosen for its boiling point turns from liquid to gas, a process which absorbs heat, keeping your food cool. The gas is then compressed into a liquid, which releases heat. Think of the propane tank on a barbecue; it gets very cold as the valve is opened, the pressure drops, and the propane boils into a gas. This is why propane is an excellent refrigerant.

An air conditioner does this too, removing heat from your home and dumping it outside. Turn the air conditioner around so that it removed heat from the outside air and moves it inside, or install a valve so that it can work both ways, and you can call it a heat pump.

Twenty years ago, most heat pump installations were “ground source” with pipes drilled into the ground and filled with liquid. Everyone called it “geothermal heating” and claimed it was renewable, taking heat from the earth or the sun that heated the earth. Calling them geothermal was a lie; it was a heat pump, moving heat from the ground when heating and dumping it in the ground when cooling. True geothermal heating is found in Iceland and Japan and may well become common with extreme deep drilling in a few years. These systems, properly installed, worked very well; the problem was that all that drilling and piping was very expensive, and you never know what you are going to hit when you drill, so pricing was always a gamble. The costs and the limitations, along with a lot of sketchy installers, limited their use.

Air Source Heat Pumps (ASHP) have been around for decades but were used mostly in warmer climates that needed a bit of heat occasionally. Their efficiency would drop significantly when the outside air is colder, and additional resistance heaters were required in northern climates. Consumers distrusted them and were often told by the trades that there wasn’t enough heat in the Canadian air. This isn’t true; there is lots of heat in the air that might be -10 Celsius, but that’s still 263 degrees Kelvin. With the development of inverter-based compressors and other refinements, ASHPs now work well in seriously negative temperatures.

Where a conventional electric heater makes heat through resistance at close to 100% efficiency, that is still way more expensive than gas. Heat pumps don’t make heat but move it, which is even more efficient, averaging 300 or 400%, which is competitive with or cheaper than heating with gas, and you get an air conditioner thrown in. They are not as efficient as a ground source system; the earth is a better heat sink and stays at about the same temperature all year, but they are far cheaper and can be installed anywhere. Finally, an affordable and effective way to heat without fossil fuels! Everyone is excited. Journalist David Roberts cheers, “Fist pumps for heat pumps!” TED talker Saul Griffith says, “electrify everything!” Joe Biden throws serious money at them.

There’s always a catch.

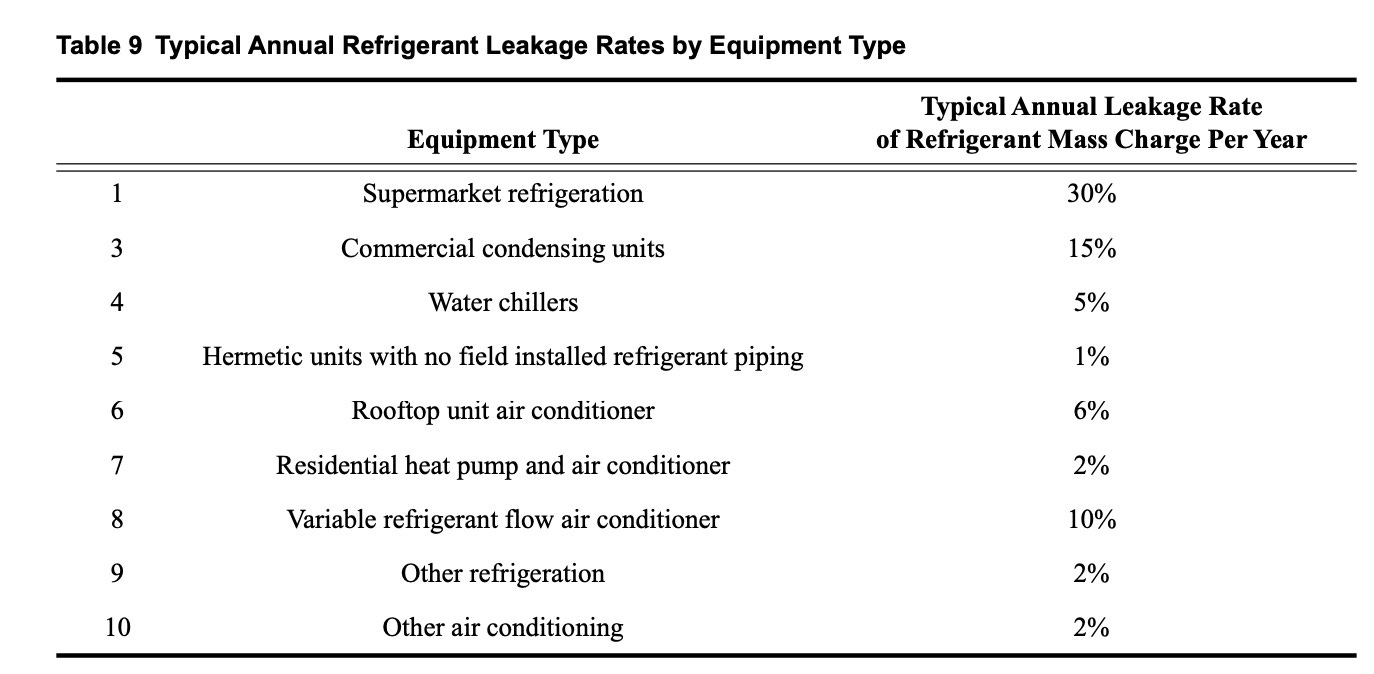

The biggest problem is that many refrigerants are greenhouse gases, and heat pumps leak, throughout their lives but also during installation and maintenance. Some claim that it averages out at about 5% per year; ASHRAE, in its new Zero Net standard, estimates different leakages for different equipment types. (5, hermetic units are what I call “monoblocs.”)

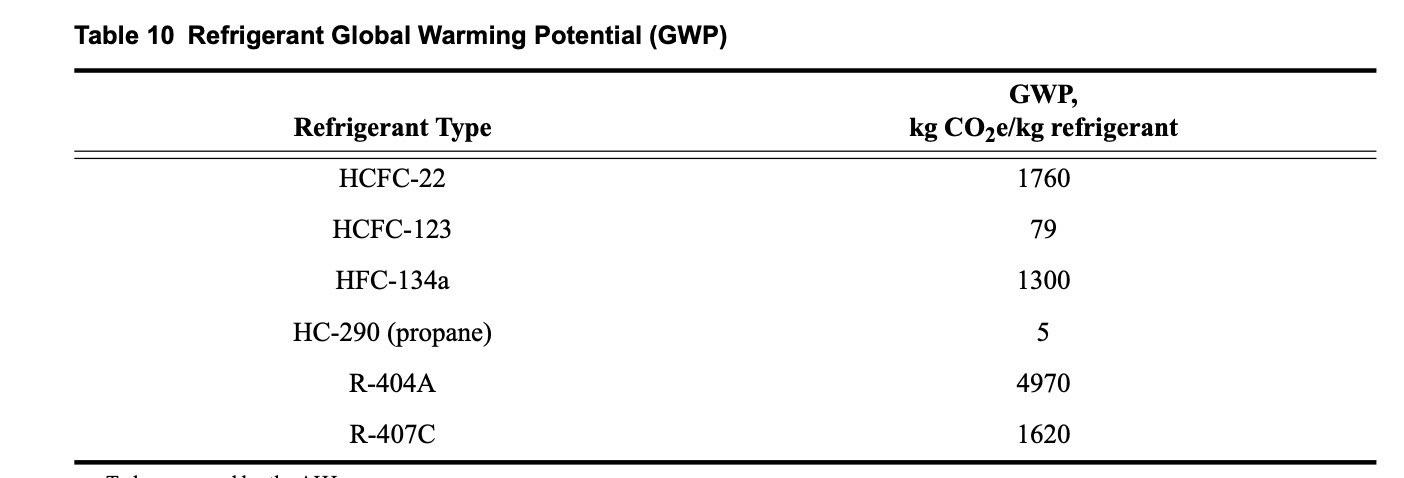

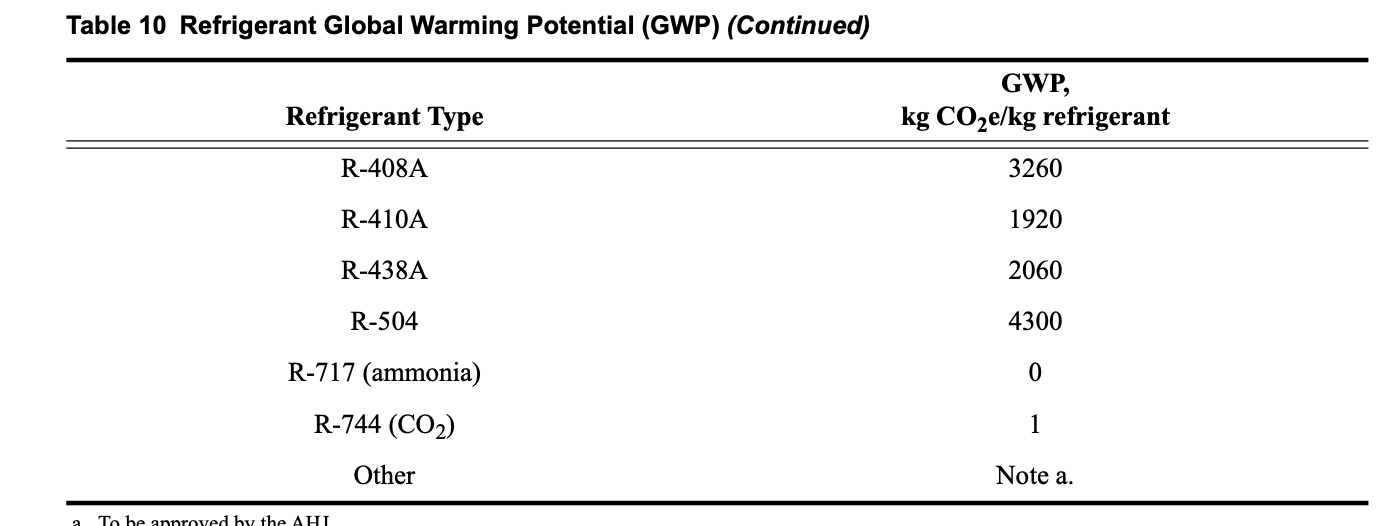

The Montreal Protocol started the process of getting rid of the worst ozone layer destroying chlorofluorocarbons (CFC) like Freon, and the more recent Kigali amendment promises to get rid of the worst hydrofluorocarbons (HFC), but even the latest and best versions of HFCs have global warming potentials of 675 times that of Carbon dioxide.

Some refrigerants have very low GWP; most new fridges are filled with butane, but fridges don’t need much refrigerant. Carbon dioxide has the lowest GWP, but CO2 heat pumps can only heat, not cool. Propane also works well, but it is obviously flammable, and the amounts permitted are limited. The other problem with it is that it is cheap and available anywhere, whereas there is big money for Dow and Honeywell in making fancy proprietary HFCs. So they screamed, “FIRE!” They delayed the approval of propane (known as R290), even though it has been used in Europe for years. Because it is flammable, it is limited to a maximum weight of a kilogram or 2.2 pounds, a tenth of what everyone has in their barbecue tanks. In Europe, you see all kinds of R290 heat pumps; In North America, you can’t find them. As Phil McKenna of Inside Climate News notes, “U.S. safety standards and local building codes would have to adopt the new international standard before U.S. retailers can sell air conditioners and heat pumps that use propane or other hydrocarbon refrigerants. That process could take years.”

You will hear a lot about the greenhouse gas problem from HFCs and the fire danger from R290 in the next few years as fossil fuel interests try to hang on to home heating. Still, the HFC leakage problem, while serious, is minimal compared to the CO2 released from burning gas, and complaining about 2.2 pounds of propane outside your home compared to piping an explosive gas inside your home into your furnace and water heater is just ridiculous. They will talk about how you need a second source of heat for resilience; what if the electricity goes out? They don’t mention that furnaces and modern water heaters all have electrical connections for fans and pumps.

The solution to the leakage problem is twofold: use a “monobloc” design where all the refrigerant is in the outside unit and a separate water loop brings the heat or coolth inside. In colder climates, this adds a bit of cost for antifreeze. But with monoblocs, installers do not need special refrigerant training; any plumber can do it because the refrigerant is sealed inside the unit.

The second, more difficult step is to design our homes around the maximum capacity of an R290 heat pump. This will require better insulation and windows, and the bigger the house, the higher the standard. This will also address resilience; a well-insulated house stays warm for hours or days when the power goes out.

“Fist pumps for heat pumps!” Has a nice ring to it. “Fist pumps for R290 Monoblocs!” Doesn’t roll off the tongue so nicely. But this is what we need for the heat pump revolution.