Counter Intelligence: Australia bans engineered stone

What are the alternatives to Ceasarstone and others like it?

Happy holidays to all! I will likely be taking the week off and will be back in the new year.

That’s the sink in our bedroom with its Caesarstone engineered stone countertop. This was my favourite “solid surface.” Caesarstone started in a kibbutz in Israel just outside of Caesaria, hence the name. It's a mix of 93% quartz and resin; Dupont makes a version, Zodiaq, with Quebec quartz. It’s everywhere now, thanks to massive imports from China, India and Vietnam. Like most solid surfaces, it's VOC-free, inert, and easy to maintain.

It’s also now banned in Australia as of July 2024 because when it is cut, it produces fine silica dust, and workers breathing it are dying of silicosis. A recent report from Safe Work Australia was damning and called for “a prohibition on the use of all engineered stone, irrespective of crystalline silica content, to protect the health and safety of workers.” The report notes:

Engineered stone is physically and chemically different to natural stone. The high levels of RCS [respirable crystalline silica] generated by working with engineered stone, as well as the differing properties of this RCS, are likely to contribute to more rapid and severe disease.

There is no toxicological evidence of a ‘safe’ threshold of crystalline silica content in engineered stone, or that other chemicals found in engineered stone do not pose a health risk to workers.

Silicosis and silica-related diseases are preventable. However, a persistent lack of compliance with, and enforcement of, the obligations imposed under WHS laws across the engineered stone industry at all levels have not protected workers from the health risks associated with RCS.

Engineered stone is hot these days; according to The Freedonia Group, “Demand for engineered stone countertops is expected to rise 9.6% per year to 404 million square feet in 2026, solidifying the material’s position as the most popular type of countertop in the country.”

But those booming sales are causing booming numbers of silicosis cases. A study, Current global perspectives on silicosis, notes that “Recent outbreaks of silicosis associated with the fabrication of domestic kitchen benchtops from high‐silica content artificial stone have been particularly notable because of the young age of affected workers, short duration of RCS exposure and often rapid disease progression.”

In California, some authorities are calling for a ban, but of course, the industry opposes this. According to the LA Times:

The Agglomerated Stone Manufacturers Assn., an international group representing manufacturers of engineered stone, maintains its products can be cut “with no safety issues or health hazards if it is performed according to the best practices.” In a statement, the association said the risk lies not with engineered stone itself, but poor adherence to safety measures by fabricators, arguing that safety regulations need to be “simplified and rigorously enforced.”

Notwithstanding the Australian complaint of “persistent lack of compliance,” that kind of argument usually holds sway in the USA, so it likely won’t get banned. But reading reports like Deadly Dust: Engineered Stone Is Making California Workers Sick suggests that designers shouldn’t be specifying it and consumers shouldn’t be buying it, so what are the alternatives?

Counterintelligence: Greener, healthier alternatives

Every year, I give a “counterintelligence” lecture to my sustainable design students at Toronto Metropolitan University, mostly from the School of Interior Design, looking at the pluses and minuses of different materials. Kitchen counters are such an interesting subject because there are so many alternatives, and it is one of the few items that a homebuyer has much choice about. It is such a visible statement; I used to complain that “people won’t pay for energy efficiency, but they will for granite counters!” Here’s my overview of alternatives:

Corian

Corian was the first of a number of "solid surfaces" where various materials were mixed with acrylic resins. Corian is marketed as a “green and sustainable material” good for lots of LEED points, being durable, low VOC, and non-toxic. They go on for pages about Greenguard, Living Building Challenge red list free, BREEAM and the AIA materials pledge. But even though it has been around since the seventies, until recently, it was really hard to actually find out what it was made of. Now that we are in the age of Environmental Product Declarations, we can get the dirt:

Wait a second, aluminum trihydrate? This is “natural” like arsenic is natural. It’s also known as aluminum hydroxide, which is cooked out of bauxite, most of which goes on to become aluminum. Left behind is toxic “red mud” which regularly causes environmental damage, most recently in Brazil. As I noted in my post, What colour is your aluminum? Bauxite mining is an environmental nightmare. As author Carl Zimring notes, “As designers create attractive goods from aluminum, bauxite mines across the planet intensify their extraction of ore at lasting cost to the people, plants, animals, air, land and water of the local areas.”

I am sorry, but I have trouble calling anything made from bauxite “natural,” let alone green and sustainable.

Granite

I have always hated granite countertops. It’s so hard that stuff breaks if you're not careful. It’s porous and veinous and needs to be sealed, or it can harbour bacteria. Some of it is radioactive.

It was not traditionally used for countertops. Years ago, it came from Quebec and Vermont and was custom-cut for buildings. There was granite all over the world, but shipping was really expensive, and in many countries, there weren't trained people who could work with the stuff. So what changed?

It got containerized, commodified, computerized and globalized

The biggest development in the granite business was the shipping container, which dramatically dropped the cost of shipping anything around the world. If it could fit in a box then it could go anywhere. But what would they ship in that box?

A key insight was that it might take a lot of skill to do custom granite, but it doesn't take much to slice it up, so the 3/4" slab of granite essentially became the international standard. This worked really well because you could slice it at the quarry, ensure that the pieces are not cracked or flawed, rack them and ship them.

With commodification and containerization, granite could be sourced and shipped and manufactured anywhere and today it comes from India, Brazil, China, and Africa. Add in the fact that it got computerized, with giant tools that cut out granite like a CNC cutter cuts out plywood, and you have an international market in a thin veneer of granite. A builder in Houston might order a Brazilian granite and send the plans to China, where they cut it to size and then ship it to America. They can do this and install it for a couple of bucks per square foot because back in Brazil or India, it costs a couple of pennies.

Really, the stuff makes a lousy counter that is subject to contamination, the workers who extract it are exploited, it is shipped all over the world chasing the cheapest labour to extract and then cut it, and it may even be radioactive. I can't imagine why anyone wants it.

Stainless Steel

Stainless steel countertops are almost standard in restaurants. It's easy to clean, durable, almost indestructible and recyclable. It's also noisy, expensive, gets scratched easily and shows every fingerprint that goes near it. It's pretty much all custom-made, although commercial kitchen suppliers do have some standard units that can work as islands.

The manufacturers claim that "Taking into account its recyclability, reuse, long life, low maintenance and product safety, the emissions from the production and use of stainless steels are minimal when compared to any other alternative material."

But this is what has been called the lifecycle carbon trap, where we worry about a 50-year time frame instead of the carbon emitted now when every gram counts against the budget to stay under 1.5 or 2 degrees. 3.3 tonnes of CO2 are emitted producing a ton of stainless steel.

Icestone

I would normally not get excited about a cement countertop. Icestone says it’s “Made from three simple ingredients – recycled glass, Portland cement and non-toxic pigment – it does no harm to the earth.” But we know perfectly well that making Portland cement does serious harm to the earth, emitting a tonne of CO2 for every tonne of cement. The counters also require sealing and waxing.

But the company is pretty amazing.

“The founders set out to create a business that integrated sustainable, responsible practices from process to product, and to provide a high design solution that would address a real need. Since then, IceStone has diverted over 20 million pounds of glass from landfills.”…

“IceStone’s commitment to second chances goes beyond our factory and our products. We hire the homeless, refugees and train the formerly incarcerated and ensure that everyone gets paid a living wage and has access to subsidized health insurance and a voice in the company.”

The stuff is heavy and expensive, but what a story.

Wood and butcher block

We have three kinds of wood counter at our cottage: A nail-laminated maple table cut out of a bowling alley back when I was an architect; a side table my dad made out of shipping container flooring, and a kitchen counter made of plywood. Many people have butcher block counters, but mixing wood and water doesn't always work out so well- our 25 year old kitchen counter is deteriorating around the sink. On the island with the stove, it's just fine.

Butcher block is a great top to work on, easy on the knives. It is naturally anti-microbial, but don't cut meat and fish on it, any more than you would right on any other counter. And watch out if it ever starts opening up at the joints. But they are actually not hard to maintain, and if you do cut meat on it, follow the advice of a writer to Chowhound: Salt.

Butchers for centuries, when done cutting meat spread their soapy or simply water moistened butcher blocks with coarse salt and let it set... Salt causes the membranes of all critters large and small to explode and die. so do it periodically, and especially after chicken and you'll never have a problem.

I think my wife Kelly would stab me with our biggest kitchen knife if I tried that; she is picky about campylobacteriosis. Perhaps it’s better to have a cutting board.

Cork

After speaking at a Passivhaus conference in Portugal a few years ago, I was invited to visit Amorim Isolamentos, a cork plantation and factory an hour out of Lisbon, and came away convinced that cork is the perfect building material. It grows on trees and is a renewable resource. Using it actually protects the environment, keeping the real estate developers from over-running the Portuguese cork forests, and protecting the habitat for the ever-so-cute Iberian lynx. Suberra, maker of the cork shown above, takes the remaining material after the cork wine stoppers are cut out, adds a tiny bit of polyurethane, and presses it into a high-density material suitable for countertops and desks. Like wood, it is antimicrobial and hypo-allergenic. The surface is impermeable and non-porous. What's not to love?

Designer Eileen Gray liked it and designed this desk with a cork writing surface, seen in her E-1027 house. She was evidently very sensitive to noise, and the cork just soaks it up.

Finally, my favourite: high pressure (plastic) laminate

I know what you’re thinking, really? But hear me out.

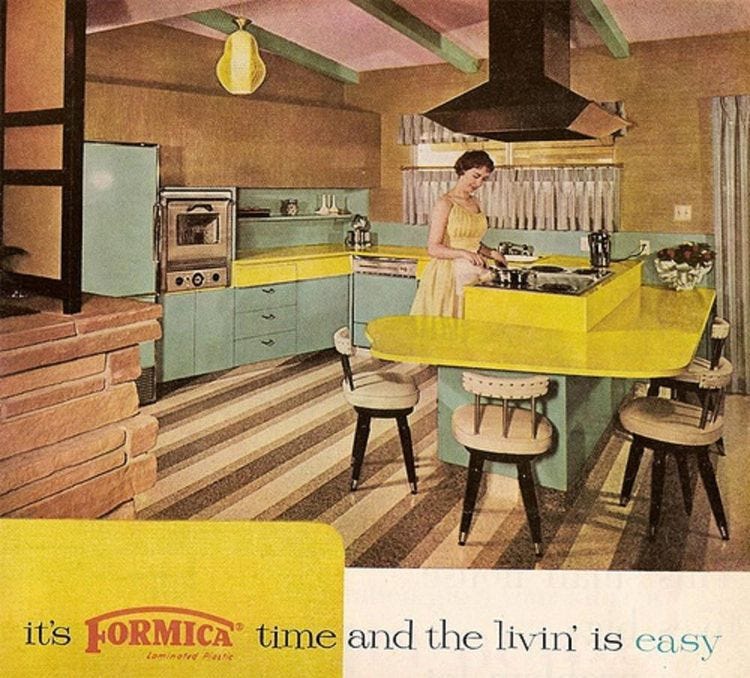

Fifty or sixty years ago, almost every kitchen counter was plastic laminate. It was a miracle material originally invented to replace mica as insulation (for-mica), made up of layers of paper impregnated with thermosetting resin (bakelite, the first commercially successful plastic). After the Second World War, they added a decorative sheet and sealed it all up in melamine. It was cheap, colourful, and a lot more durable and easy to clean than the tile or linoleum people used before. They could form it to make backsplashes and do bullnoses to stop dripping at the front. It is easily scratched, burned and stained if you aren't careful. But our kitchen counters are 30 years old and are still serviceable.

Formica is made in Cincinnati from FSC paper stock, with biomass energy management and water-based phenolic resins; they tell a good sustainability story.

But that's not the main reason I like it so much. I keep saying, “Use less stuff,” and it's the most minimal of all the counter materials, a thin paper and plastic layer that can be attached to a wood substrate. It can be moulded so that it's easy to clean. If you do damage it, it's the cheapest countertop, so replacing it won't kill you. I once made a design error on a granite counter when I was working in prefab, and it cost thousands of dollars to fix; when I made a mistake in the kitchen in our upstairs apartment, it was a couple of hundred. (I made a lot of design errors; that’s why I write now.)

Except for perhaps stainless steel, none of the other counters have any real performance advantage, and all of them cost many times more per square foot. People want granite and stone because they have been sold a bill of goods, paying more for a lousy counter because it’s all the fashion. They may look good, but they aren't practical, they aren't light, and they certainly aren't green. But laminate is practical, colourful, minimal, and did I say it was cheap?

What’s your favourite countertop? Leave a note in the comments. And see you in 2024!

It is hard to beat the price and serviceability of laminate tops. Not to mention the fact that they can imitate just about any other material's looks. That said, I'm a wood guy; I've lived in 3 homes built on wood foundations, prefer wood decking and flooring. Its hard to beat butcher block tops. They are sometimes cheaper than laminate, they age well and cuts and scratches give them character, and they exude warmth.

My favourite counter surface is the island in our kitchen. Recycled regular glass compressed into a solid unit. It can be scratched but it is beautiful and is underlit by LED 's. The other kitchen counters are icestone, which as mentioned by Lloyd, need occasional maintenance. Also the bath countertops are a compressed ground up stone with some kind of binder (not cement) and they are totally indestructible.