Cars need design for disassembly and repairability

Instead, they are going in the other direction.

Architects are talking about design for disassembly, “the design of buildings to facilitate future changes and dismantlement (in part or whole) for recovery of systems, components and materials, thus ensuring the building can be recycled as efficiently as possible at the end of its lifespan.”

More and more of our electronics are being designed for repairability. Kyle Wiens of iFixit says it’s a smart corporate move:

“Designing and building products that can be repaired and last for many years is good business: that’s why leading computer manufacturer HP brags about the repairability of its products in marketing materials…given a choice between an inexpensive product that lasts one or two years and a more expensive, repairable product that lasts closer to five years, customers typically lean toward longer-lasting, more repairable products.”

And then we have Tesla. According to energy and transport analyst Michael Sura, Tesla is “gigacasting” bigger and bigger pieces of their cars. While high-pressure die casting (HPDC) has been used to make complex parts for years, Tesla is making bigger and bigger parts. Sura writes on Linkedin:

“Traditionally, car manufacturers integrate numerous stamped, forged, extruded, and cast elements of their vehicle structures, connecting, welding, and gluing these components together in the production process. During gigacasting process, a molten liquid aluminum alloy is pressed into a mold under high pressure, resulting in the formation of large three-dimensional shapes with a relatively high level of precision. A large single gigacasted component can replace 50, 70, or even more individual parts.”

Elon Musk is proud of this, tweeting:

Tesla continues to hold onto its vision of producing cars by employing a single-piece casting technique to fabricate the entire vehicle body. Elon Musk tweeted on January 18, 2021. “With our giant casting machines, we are literally trying to make full-size cars in the same way that toy cars are made”.

There is just one problem: if the car is damaged in a crash, it is impossible to fix.

“Instead of replacing a small component or components, it is necessary to replace a whole gigacasted part. It would be possible to replace it, but the very high repair cost makes it more sense to write off the entire vehicle.”

Sura notes that other companies, from GM to Mercedes, are going with gigacasting.

Now, I am an architect writing on a computer, not an engineer building cars, but I think this is a bad idea. My first car was a 1965 Volkswagen Beetle, and it was designed on different principles: simplicity, repairability, and frugality. Just as Kyle Weins says design for repairability is good business, so did Volkswagen.

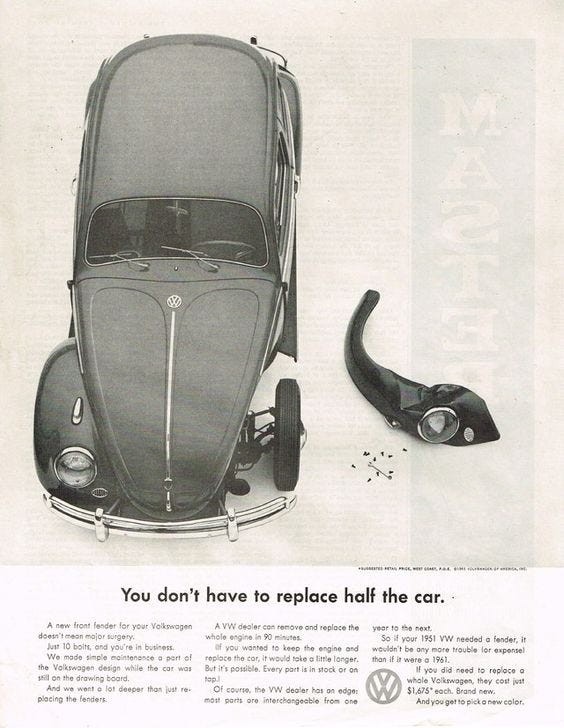

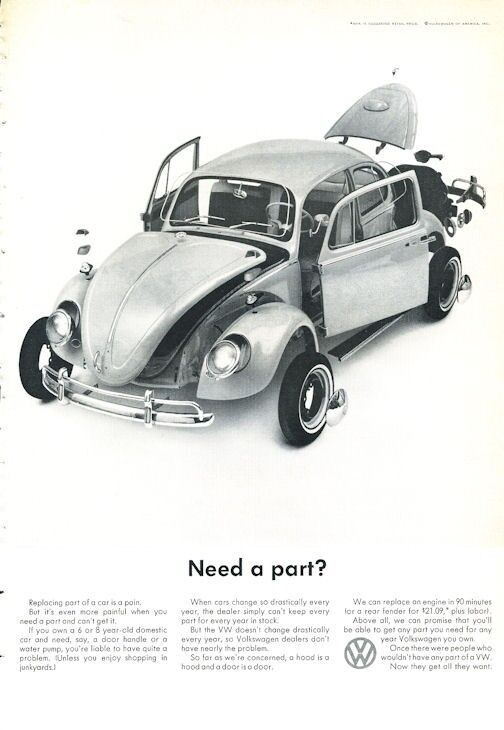

I did this on my Beetle; just ten bolts to remove the fender. It was not as easy as they suggested; my car was ten years old, and the bolts were rusty and in awkward positions. But I eventually did it.

In this rather dated and sexist ad, VW describes how the parts are interchangeable over multiple years. It may not be funny anymore, but it makes a virtue of repairability and design for disassembly.

Whereas engineer Phil notes in a comment on Linkedin:

It's blindingly obvious for any competent engineer that by replacing a hundred parts with two you create a situation in use where you cannot repair by replacement unless you take the entire front of the car off. You cannot weld castings together, you cannot replace with sheet metal repairs, you cannot bolt in a replacement casting section. You cannot bond in a repair section.

This is a design that is purely biased towards saving Tesla money during production, and also allowing them not to stock repair parts thus reducing overhead burdens. This doesn't help people that buy Teslas at all. It's already bad enough that insurers write off cars because a headlight and bumper are damaged. Affordable repair must be a part of the design philosophy with “right to repair.”

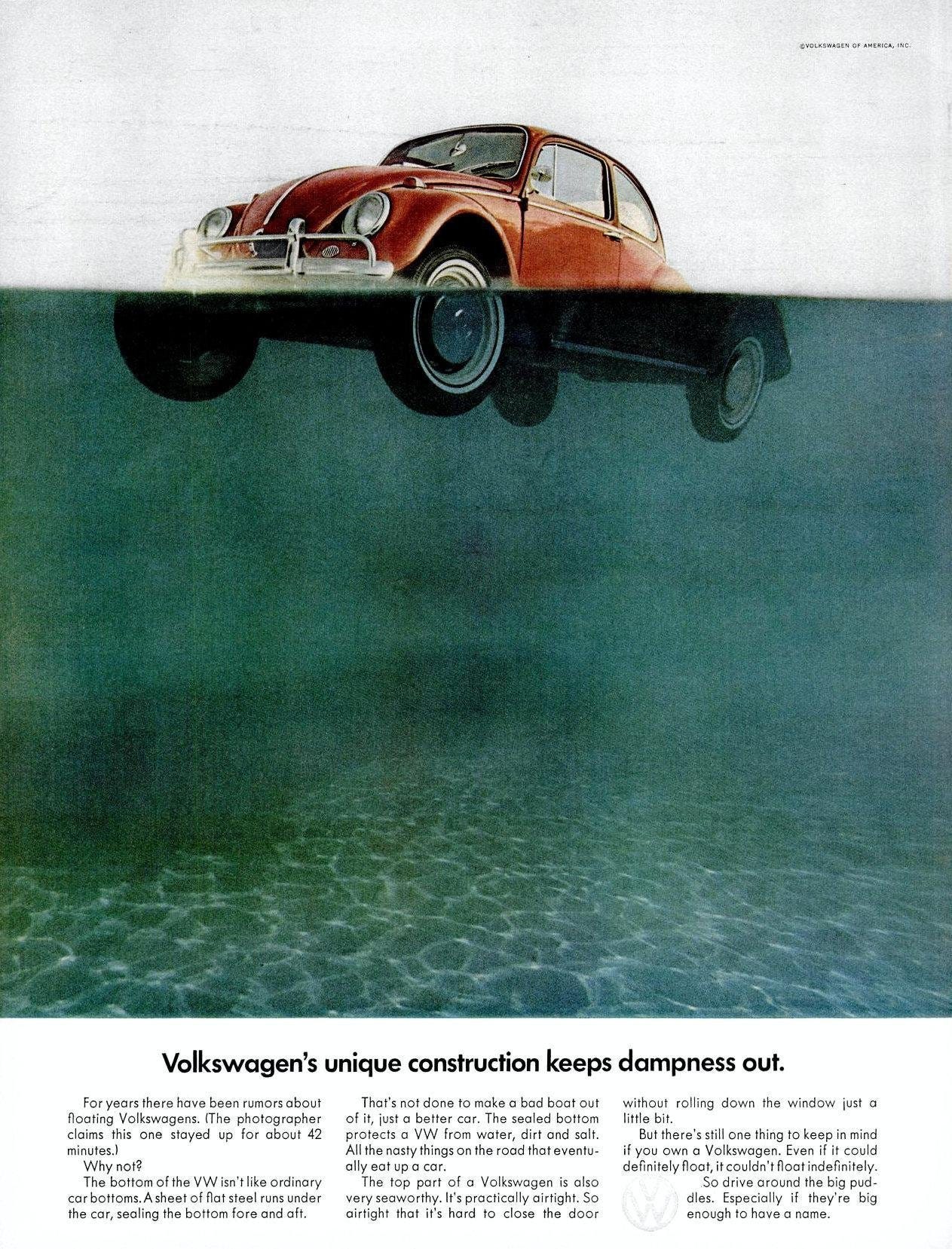

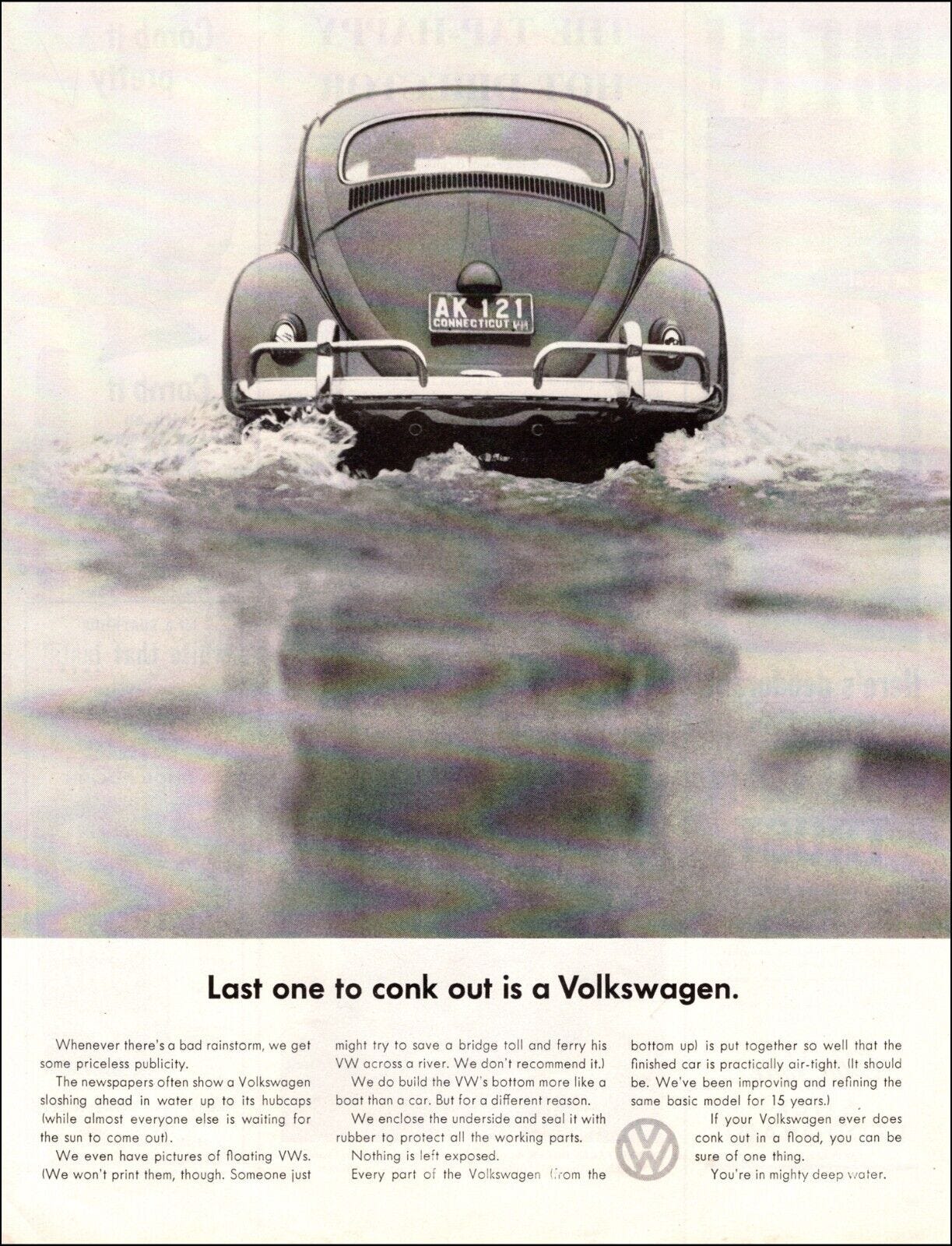

'There are other attributes of Beetles that it would be well for Tesla to emulate. They float for a while. Their windows crank open and don’t need a working electrical system.

Every big rainstorm brings photos of cars getting stuck as people try to drive them through flooded streets. Volkswagen used to market this as a virtue; I suspect that today it would be a big one.

There is a reason I drove three different VW Beetles from University until our first child was born, and we couldn’t fit a baby seat into it- they were cheap to run, cheap to fix, fun to drive and brilliantly designed. There were undeniable issues of crashworthiness and emissions, but the principles of simplicity, frugality and repairability are just as important today. We don’t accept the idea of buildings or computers that can’t be fixed- why do we accept this for cars?

Thanks, Lloyd. We agree: 0. Energy efficiency 1. Longevity 2. Repairability .

("0" because if it wastes to much energy in the time it's used, it's not a good idea that it lasts long :-).

Meanwhile, in other VW news:

"Fossil Fuels Remain The Future. VW To Invest 60 Billion Euros In Combustion Engines!

In a surprising move, Volkswagen announced it plans to invest 60 billion euros in the development of new combustion engines as confidence in electric mobility plummets in Germany and elsewhere.

“This change in strategy shows that the transition to electromobility is progressing more slowly than expected,” reports Germany’s Blackout News here. “Just last year, Volkswagen assumed that electric cars would account for 80 percent of annual sales in Europe by the end of the decade. However, the lukewarm reception for its own ID models is forcing the company to adjust its strategy.” Also see (motor1: 07.06.24).

As German sales of electric vehicles fall way short of government targets due to their unpopularity and high costs, manufacturers are seeing the writing on the wall: Electric mobility still has a long way to go.

Reality check..."

https://wattsupwiththat.com/2024/06/15/fossil-fuels-remain-the-future-vw-to-invest-60-billion-euros-in-combustion-engines/