Architects and engineers like Steve Webb are rethinking the conventional wisdom of how we build

Example: the wonderful new world of stone construction

I have been in Europe for almost a month now, killing time between two conferences and doing a lot of thinking about what was said in Paris and what I am going to say in Innsbruck or write about next. When I used to write so much for Treehugger I would go see everyone and everything on a trip, but this time the only person I asked for an appointment with was Steve Webb of Webb Yates Engineers.

Webb is a structural engineer and a leader in the movement to bring back stone as an important building material, not just for cladding and decoration but for structure. I corresponded with him earlier for a Green Building Advisor article on foundations, in which he pointed out the silliness of mining limestone, grinding it up and cooking it at 1450°C, only to mix it with more stone and water to turn it back into… stone. “Not only is it perverse to do this, but the carbon footprint of concrete is 250% higher than stone for a material with only 25% of the strength.”

Last night I saw the perversity of this in Liège, where the local stone, available in huge quantities, is hung on top of a concrete column, essentially as thick wallpaper. Why not, as Webb suggests, just build the column out of stone in the first place?

It would probably hold up to abuse a lot better than this building has.

You can walk a hundred meters and see how Belgian builders used the same stone structurally, building big frames around the windows with a little bit of brick between to space things out.

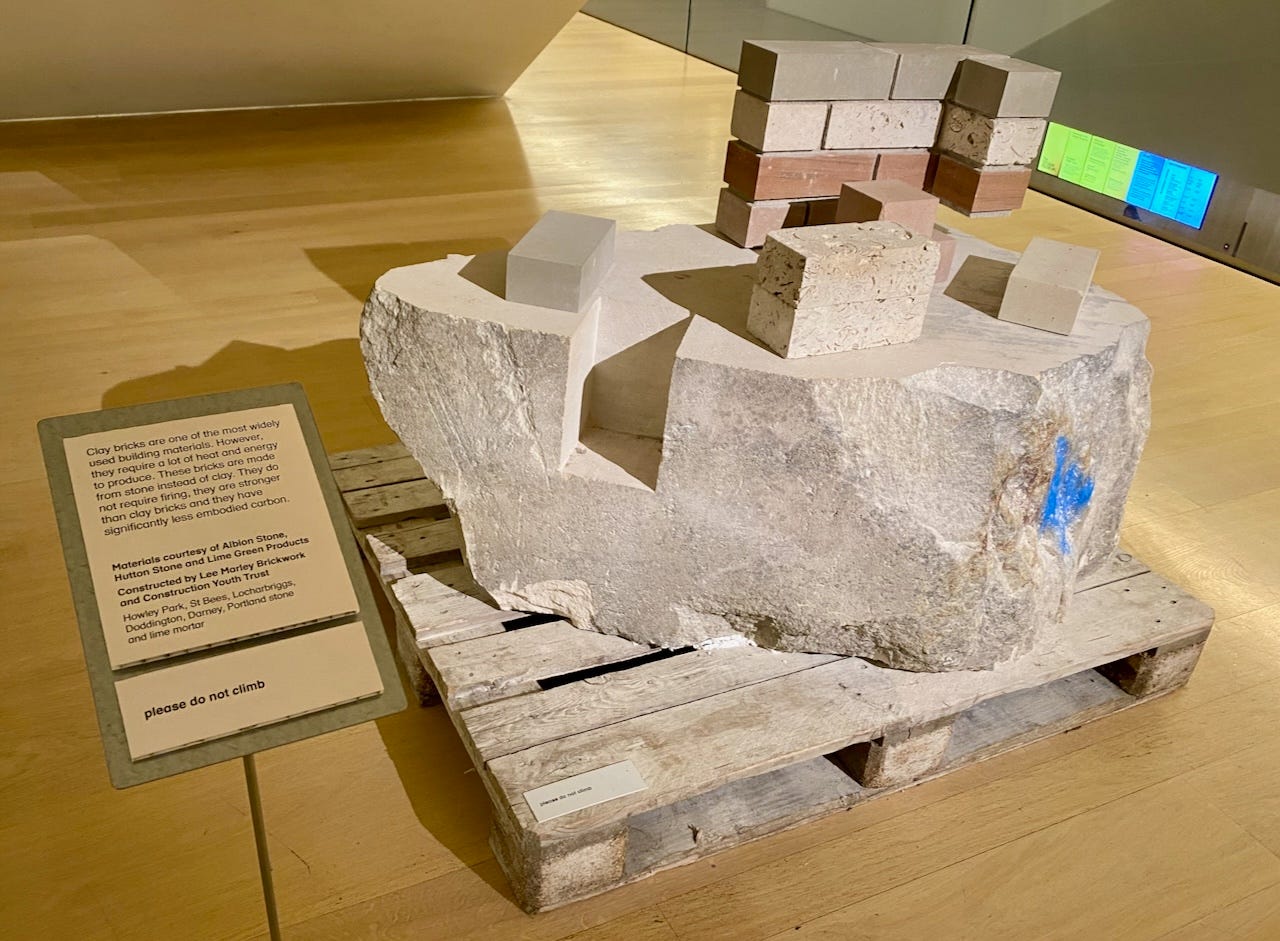

Webb would have probably preferred brick-sized stone, though he told me he thought bricks are silly, “designed around what the mason could lift easily.” This exhibit was a demonstration of how builders could keep doing what they are doing now with far less upfront carbon emissions by switching from clay bricks to stone. When asked for Green Building Advisor what the impact of this was, compared to other materials:

“In respect of quarrying, almost all construction products, such as concrete, brick or steel, come out of the ground as it is. The volume of rock available to us is infinite in comparison to construction demand. If everyone or 8bn people on the planet, spontaneously rebuilt their homes in stone construction it is a volume equivalent to a 40km square quarry 20m deep, a pinprick in the earth’s crust… Forestry takes up much more room. A tree occupies 25m2 of ground and takes 25 years to procure 1.5m3 of timber. Under the tree is 500m3 of stone that can be removed in 3 months. So in land use terms, stone is better than timber.”

I thought this was a brave soul, sitting under a barely supported slab made from thin stone squares held together by little inserts, but Webb is making the point that we know how to use stone to do many of the things that we automatically turn to concrete for. He is also doing hybrid mass timber and stone floors where stone slabs sit on Glulam beams. And if all that is a stone bridge too far, he makes a strong case for stone piers instead of concrete foundations.

This photo, from the New Stone Age exhibition at the Building Centre in London and built in collaboration with Groupwork Architects and The Stone Masonry company, shows how limestone blocks can be quarried, cut with a CNC saw, drilled and then held together with cables to make a pretensioned floor slab. “In using this naturally occurring material, with minimal post-extraction tooling and manufacture, structural stone flooring can have a carbon footprint of only 15 percent of its hollow core concrete (with steel reinforcing) equivalent at the same cost.”

Just because Steve Webb shows that you can build roof trusses out of stone doesn’t mean that you should; wood might do a better job for that. But it is an interesting provocation; Steve Webb writes in the RIBA Journal: “The desire in general building practice in wealthy economies is to limit expensive man hours – both in design and execution – and use cheap materials instead. Over-rationalised structures save design and construction time, but with the by-product of maximising carbon.”

I wanted to meet Steve Webb because he presents such a radical alternative to the conventional wisdom. Looking back at my time in London, I wish I had done more aggressive interviewing and less introspection; there is so much going on in the UK, so much creativity and ingenuity. I need a year, not a couple of weeks!

Another huge advantage of using stone for structure is the lifespan of the building - hundreds of years instead of 55-60.

Planned obsolescence in building - not carbon-friendly!

This is fascinating. I’ve just sent this article to a couple of structural engineers that I work. Thanks for shining a light on this innovative approach. Everything has an environmental impact, and frankly I’ve been concerned about mass timber ever since it became the next big thing. I’m eager to think about how a stone structure might be enclosed using modern building science. Maybe it’s just the same as for concrete.